The design world is getting bigger day after day. As a result, there are many new technologies launched in the market to help designers and professionals to express their ideas clearly and realistically.

To benefit from these technologies, some crafted pieces of software are highly needed. This is exactly where SolidWorks and Fusion 360 come into play.

It is true that both of them are famous and used by many professionals. However, there are many differences between them. That is what we are going to talk about in this article.

Solidworks vs Fusion 360: how to really choose?

Used in animation, game design, architecture, furniture design, manufacturing, interior design, and product design, 3D models play a crucial role in digital and physical production.

Finding the correct 3D modeling software for your needs isn’t as straightforward as simply picking one in a random way. Here’s where comparison articles come in very handy. They will help you a lot to see, head to head, which software is better for you. We had already compared Fusion 360 to a bunch of other software:

On the other hand, we also reviewed and compared SolidWorks versus other programs as well:

In today’s article however, we have a brand new ultimate face-off: SolidWorks vs Fusion 360. Let’s dive right in!

Brief background

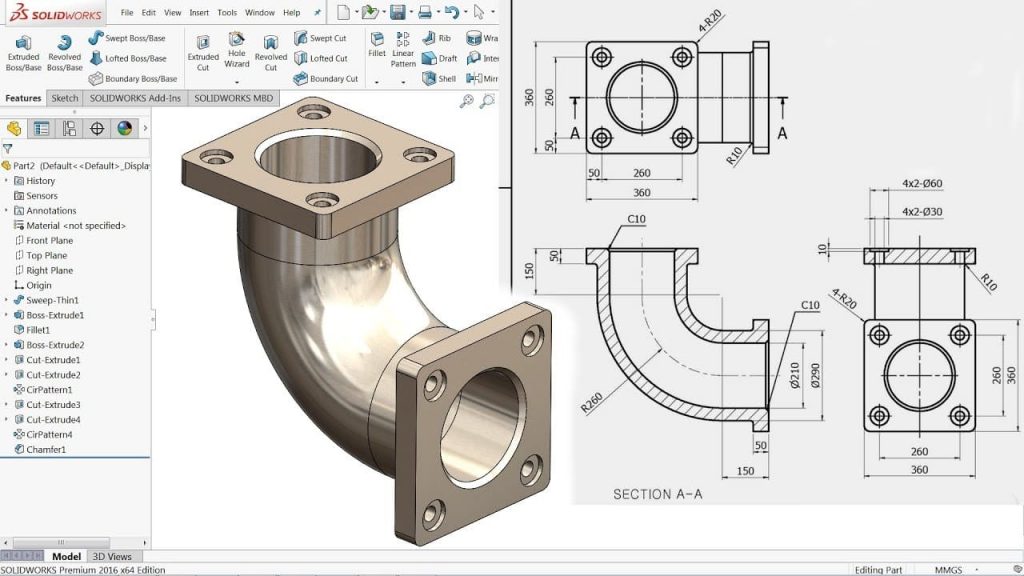

SolidWorks is software created in 1993 by Jon Hirschtick, and purchased on June 24, 1997, by the company Dassault Systèmes2.

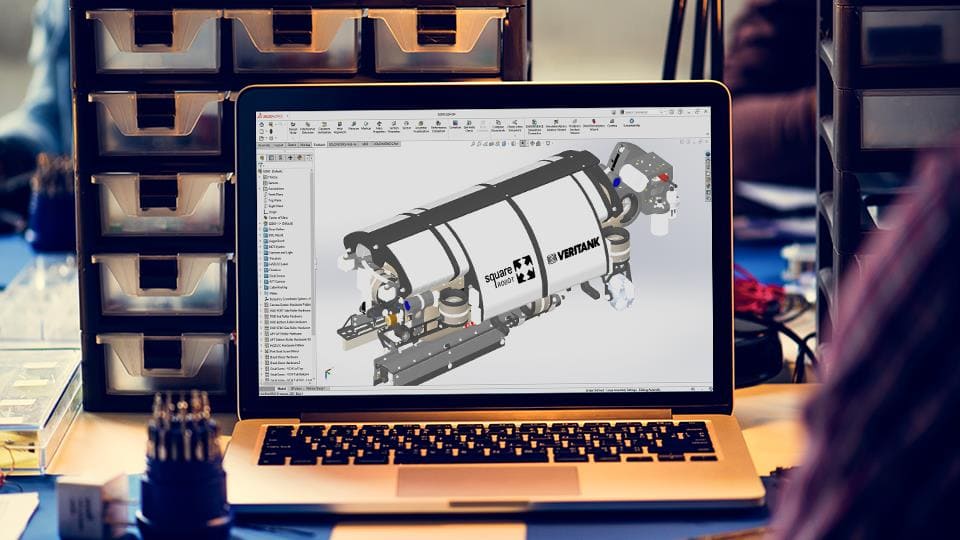

This software, which is also known as “DSS SolidWorks” referred to its developer, is a CAD software used to create 2D or 3D solid models easily. It is considered as CAD software with High productivity (up to 95%) that provides many impressive features, such as better design visualization, better products, faster iterations, improved communications, and design with fewer errors…

Official Website: https://www.solidworks.com/

Fusion 360 is a 2D/3D CAD software developed by Autodesk that was officially launched as a commercial product in 2013. So, it is a fairly young program.

This software has found its balance between engineering and 3D design. It is considered a user-friendly and versatile software that enables the integration of design processes from design and simulation to manufacturing.

It is a new and simplified approach to parametric modeling, which Autodesk renews with each new release. Fusion 360 meets the expectations of entrepreneurs, engineers, and designers in 3D CAD.

Official Website: https://www.autodesk.com/products/fusion-360/overview

What are SolidWorks and Fusion 360 used for?

SolidWorks is a 3D modeler that uses a parametric design. It generates three types of files relating to three basic concepts: the part, the assembly, and the drawing.

These files are related: if you try to modify a part of the design you are creating, the result will appear in all the files concerned. It is used to develop mechatronic systems from beginning to end.

At the initial stage, the software is used for planning, visual ideation, modeling, feasibility assessment, prototyping, and project management. The software is then used for the design and building of mechanical, electrical, and software elements.

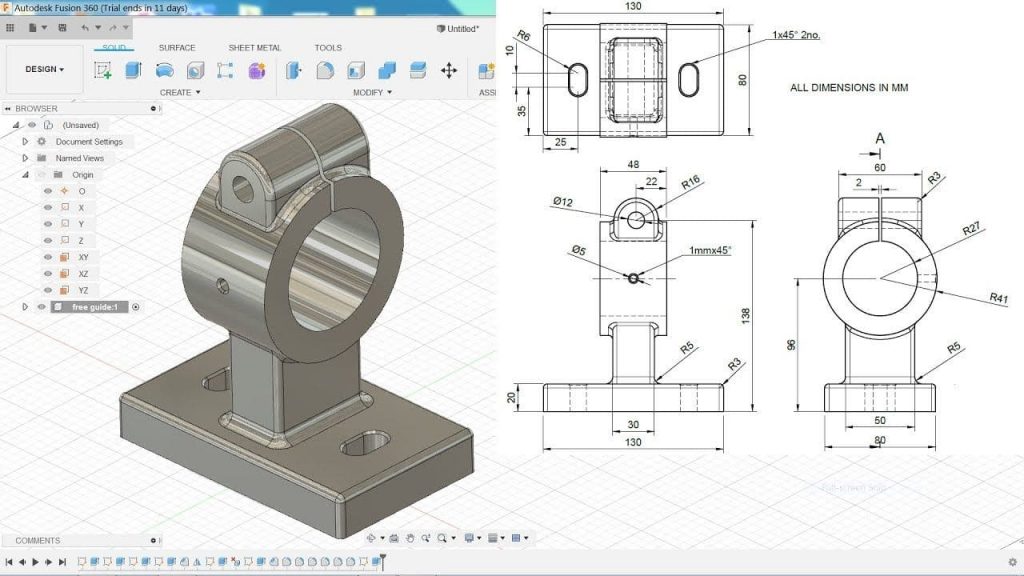

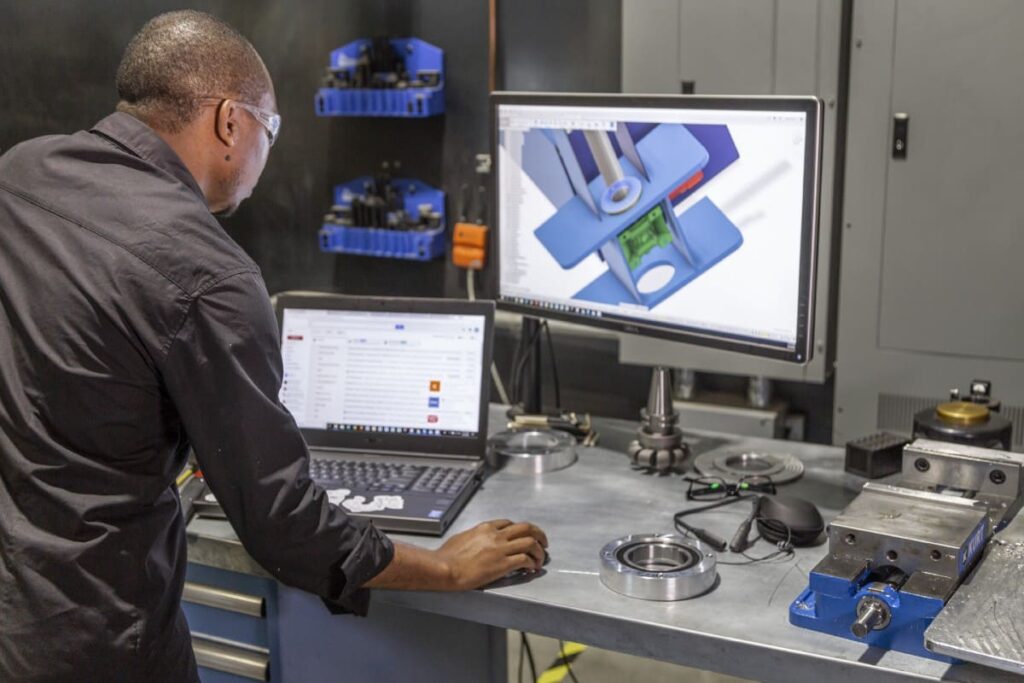

Fusion 360 is used to create 2D and 3D designs. What sets Fusion 360 apart from other modeling software is that it allows in an environment: parametric modeling, surface modeling, and polygonal modeling.

To take advantage of the possibilities offered by this technology, you must not treat each modeling mode approach separately, but you need to combine the tools from the three environments to reach the best results.

Many tools for manufacturing are integrated into Fusion, allowing for Planning, Generation of toolpaths, assembly management, and simulation. The special thing about Fusion 360 is that it utilizes cloud technology in a way that not many other CAD programs do.

What are the modeling and designing differences between SolidWorks and Fusion 360?

SolidWorks and Fusion 360 are both used to make drawings and create models. But the process of creating these models is not the same! There are some differences that we are going to point out.

SolidWorks, as you clearly understand from its name, is primarily a solid modeler. It is parametric, which means you assign dimensions to your geometry that will be applied directly.

You can build your design with surfaces, and also create any shape you can imagine if you give it enough time and good practice. This software benefits its users with a Solid modeling feature to create designs, but there are some limitations.

These components are good at capturing manufacturing data, such as mass, weight, etc. But they have some limits and put banners in your way while creating designs. Often, your models will appear somewhat boxy and dull. The best way to benefit from this software is to use both surfaces and solids to achieve truly realistic models.

It comes with a box of tools that you can use freely. This software is mainly known for its 3D features, but you can also draw 2D designs in it; however, it should be reserved for annotations. Ideally, you should use your 3D models to create 2D drawings.

SolidWorks drawings comprise at least one view generated from either a part or assembly.

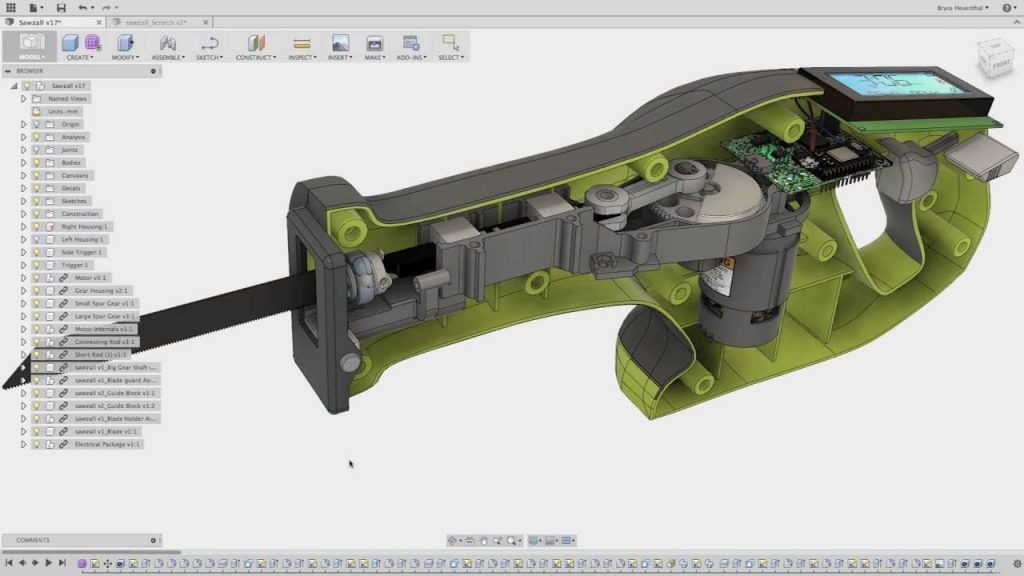

Fusion 360 offers several modeling environments for different types of modeling from technical details to organic surfaces. The user interface with Fusion 360 is straightforward and it has drawn inspiration from Google’s Sketchup in its layout.

Designers and engineers can take advantage of this CAD software to explore potential shapes for attractive and dynamic consumer products. The first environment of this software is parametric modeling, which is based on 2d sketches, forming a closed network of curves (Profile).

The relationships between sketch elements and dimensions are defined in the sketch and reflect the design intent. The second environment is surface modeling. It contains surface creation tools (extrusion, sweep, etc.) that allow surface creation based on sketch profiles.

In this environment, a closed solid can be decomposed into its constituent surfaces. The third environment is polygonal modeling which allows:

- Creating of organic or ergonomic shapes in the software’s sculpt space.

- Creating of a TSpline from primitives (boxes, cylinder, etc. …)

- Creating from profiles (closed curves) by extrusion, sweeping and so on.

- Transforming a surface created from the Model environment (solid modeling) or Patch into a TSpline to edit the shape.

Long story short, Fusion 360 comes with many tools that should always be combined to make the process of designing products easier and give better results.

Can we create animations with SolidWorks and Fusion 360?

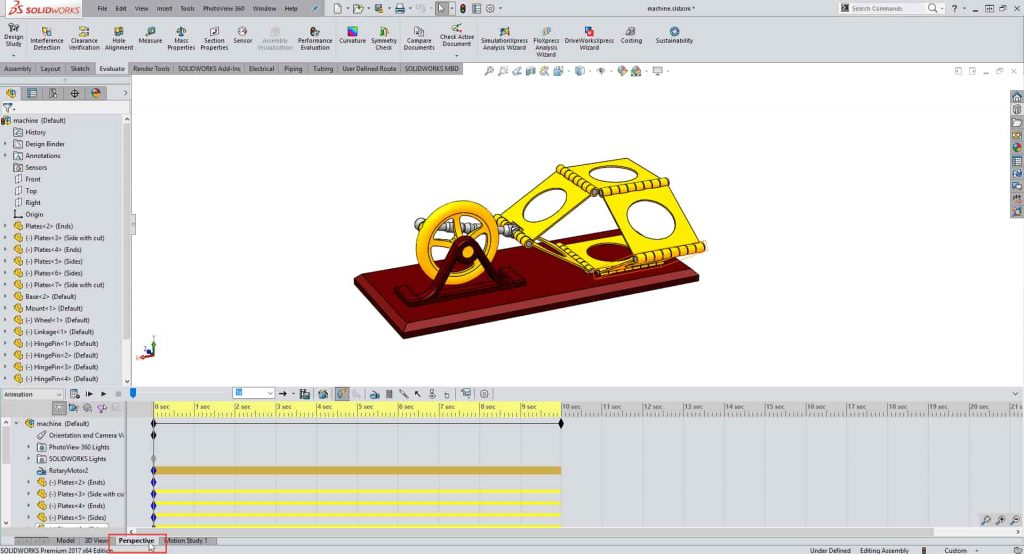

Yes, you can create animations and realistic simulations with both SolidWorks and Fusion 360, but not in the same way.

In SolidWorks, you can create animation by dragging the time bar along the timeline to the specific point you choose, and then drag the component you want to create animation with to a target location.

The Motion Manager moves the component from its initial position to the position you designated at the specified time. Use the ‘Animation Assistant’ to create animations or to add rotation, bursts, and gatherings to existing motion studies.

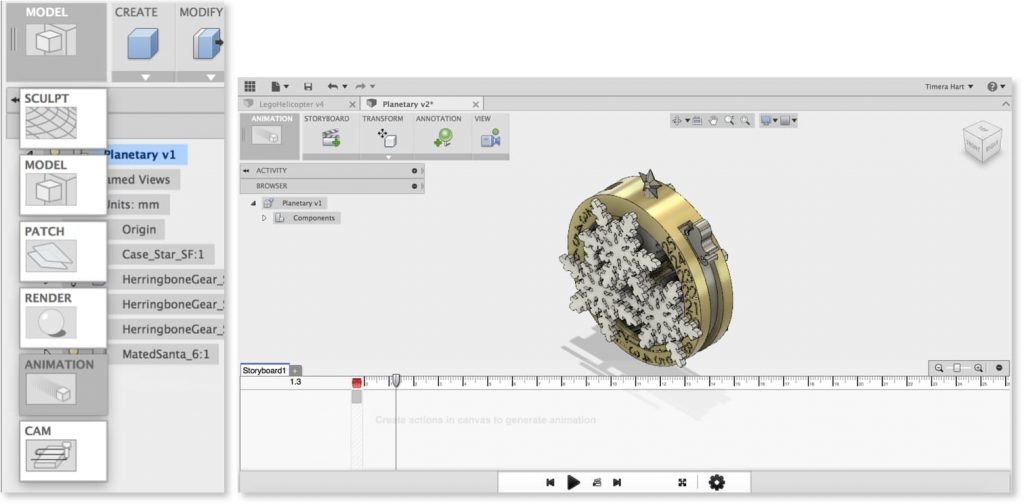

Fusion 360 supports keyframe animation so as to make all kinds of animations for your assemblies, such as engines, gearboxes, and more. By using the Transform tool, you can move your components to animate them in a timeline.

Just keep in mind that the organization of your components matters here, and complex animations should probably be done in another tool specifically for animation.

In general, Fusion 360’s animation feature is best-suited for simple visualization.

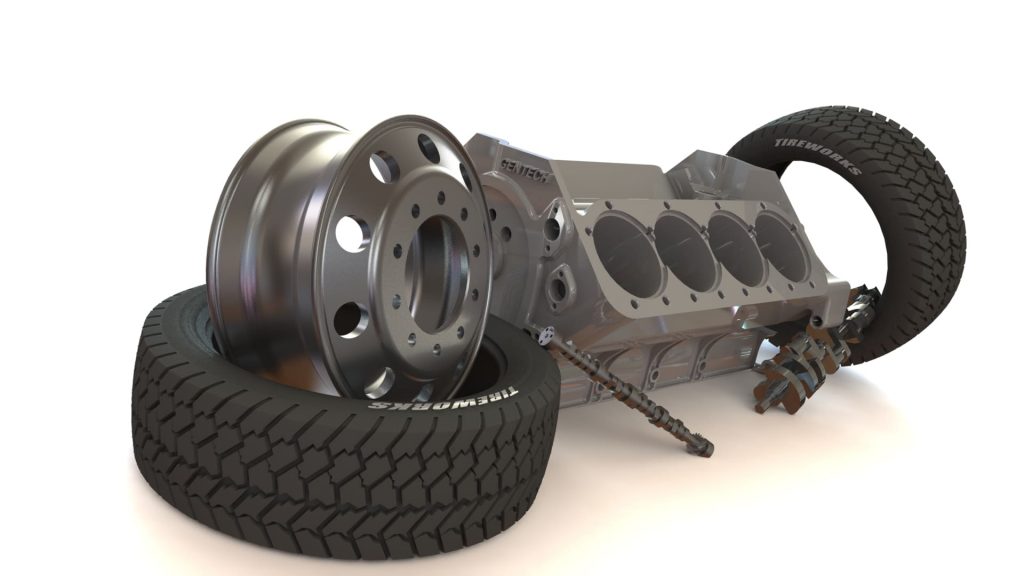

Rendering in SolidWorks and Fusion 360, is it possible?

The answer is YES. It is possible to render with both software to get realistic results.

It is possible to create photorealistic renderings with SolidWorks by using PhotoView 360, which makes things so much easier.

PhotoView 360 is a SolidWorks recent add-in that produces photo-realistic renderings of models. It allows you to manipulate the appearances, lighting, scene, and apply many other specifications to the model. PhotoView 360 is available with SolidWorks Professional or SolidWorks Premium.

By these simple steps, you will be able to have a realistic final rendering, you just have to click Tools > Add-In PhotoView 360, start a preview in the graphics area, edit appearances, the scene, decals, and lights. When you feel that your design is ready to render, perform a final step by choosing PhotoView > Final Render.

In Fusion 360, there is no need for any adds-in, you just have to head over to the model or patch icon and hover over it to get a flyout that lets you select render.

Once in the rendering workspace, you will see the background and model change a little as it is optimized for visualization. You will also notice the toolbar has tools to control materials, environment, and quality of rendering.

You need first to apply materials to your design with the workflow, you can give specific material attributes to your model. For example, you can set your solid bodies to be “made of” marble, wood, various metals, glass, and more before changing the Environment Style with a choice of 8 different styles and be able to rotate the light source to control where highlights show up on your design.

Fusion 360 gives you the right to choose the type of rendering process: it can be quick, normal, or advanced. It is recommended to use a quick render at the beginning to see how things look, then make adjustments to materials and environment before you render with Advanced.

Rendering time can vary depending on assembly size, reflectivity, transparency of parts, and a few other variables.

Industries that use them

SolidWorks is used by a large class of industries, technical drawers, engineers, and specialists, but it is specifically designed for mechanics, designers, and building professionals. It is used in medical device companies, transport factories, and technical services.

Fusion 360 is indeed considered as a young software compared to SolidWorks, but it is used in many fields and by many industries: Electronics and Electronic Components industries such as Samsung, by furniture designers, and also in aerospace companies.

Ease/difficulty of learning

Beginners will find some difficulties using SolidWorks and Fusion 360 because they both require some basic information about using CAD tools. You are probably wondering which one is easier to learn and use.

SolidWorks is a good tool for mechanical engineering design jobs; it makes the process of creating a 3D result of a piece of a machine or even a building easier. Its interface contains some powerful tools, but few people use them.

Fusion 360 is not so difficult; it has a complete suite of 3D modeling tools, making it quite easy to create solid models. Moreover, this software is flexible and a bit easier to use with a great push/pull tool allowing to create great organic geometry and surfaces.

In which devices can we use SolidWorks and Fusion 360?

SolidWorks is not only available on Windows and Mac but also in touch, pen, or Dial Input devices to guarantee a better experience. When it comes to Autodesk’s Fusion 360 it is available both for Mac and Windows users.

The hardware is another story (a pretty long one actually). This is why we decided to create a detailed post about the best way to choose a computer as an architecture student.

SolidWorks vs Fusion 360 Pricing/Licensing

SolidWorks price tag is summarized in the Standard License for $3,995. The Annual Subscription service for a standard license, which covers technical support, upgrades, and more for one year, is $1,295. However, this software offers a free 12-month license for all qualified educators, makers, hobbyists, military, and sponsored organizations. You also have the SolidWorks for students option.

When it comes to fusion 360, as a hobbyist, student, or even an entrepreneur, you could qualify for a free license. Fusion 360 for students and educators is free of cost, in which case you can obtain a three-year subscription.

You can also get a free license if you are engaged in a hobby business, and your revenue does not surpass more than 100,000 USD annually or using it for your projects outside of your primary business. If you do not fit any of the cases above, you can still acquire it with an annual subscription of $495/year (or $60/month).

Conclusion

Architects, engineers, and designers do not have the same needs when it comes to CAD modeling. SolidWorks and Fusion 360 are two good programs, no doubt about it.

But product designers and mechanical engineering experts will not need the same features and will use the program differently. Some CAD tools can be more needed in some sectors.

SolidWorks can be the perfect solution for some 3D modeling users while Fusion 360 will match the needs of other users. That is why you should know that you cannot decide which one is better.

Actually, you need to understand and self-analyze the various options available in both software and then find out your business needs, budget, and skill levels, which play an important role in deciding which software suits your needs.