Today we are going to take a closer look at the history of 3D printing, which has become a very important subject to many industries as much as for simple people!

The name “3D printer” is said to be based on the product name “3D printing” by company Z, which was a manufacturer of full-color 3D printers, that was later acquired by 3D Systems. The company’s products used the additive manufacturing method developed by the Massachusetts Institute of Technology (MIT). The additive manufacturing machine uses an inkjet method that blows out adhesive and color ink that hardens the gypsum material from the nozzle, and the mechanism was like a printer, so it seems to have been named so.

Currently, various manufacturers use the term “3D printer” for additive manufacturing machines other than inkjet type. In this way, 3D printers can be interpreted as a kind of marketing term rather than a technical name.

In addition to 3D printing, additive manufacturing is also called “additive manufacturing” (AM, additive manufacturing). It seems that there is no strict definition for the proper use of each name. all additive manufacturing methods are unified with “3D printer”.

The Start of 3D Printing:

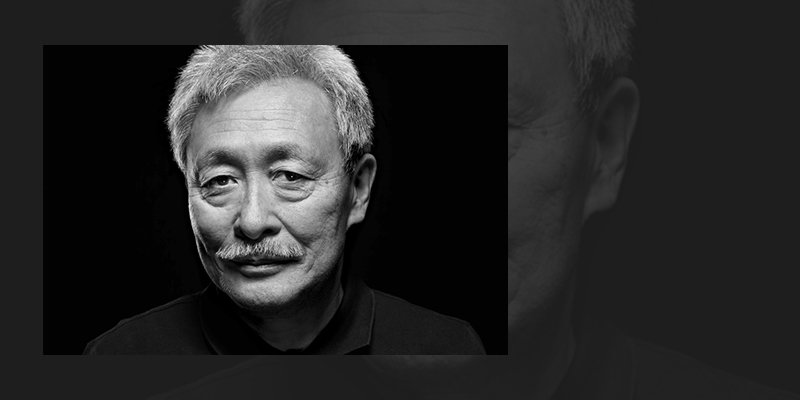

In fact, it was the Japanese who first developed additive manufacturing technology. Hideo Kodama is a researcher at Nagoya City Research Institute. Kodama was originally involved in semiconductor processing technology and photoresist technology and devised the “stereolithography method” based on that knowledge. He applied for a patent in 1980, but for some reason, he applied only and was left without a request for examination.

Later, an American invented the stereolithography method that Kodama thought about in 1983 and obtained a patent. That person is Chuck Hull, the founder of 3D Systems. By the time Haru got his patent, Kodama’s application had already expired. If Kodama had filed a request for examination and had obtained a patent, it may be that the manufacturer in Nagoya had the top share of 3D printers by this time.

All data is before that time period, which allowed the inventor, “Charles Hall” to register the invention of the name “anthropomorphic device”, a name that he invented in 1983 and set out to establish the “3D Systems Corporation” company, the largest digital printing company to this day.

https://www.3dsystems.com/3d-printers

In 1986 the 3D printer was born . Since then, research on 3D printer technology has advanced in the United States.

In 1987, 3D Systems unveiled the SLA-1, the first commercial version of a 3D printer known to the world, and the same year an American researcher registered the patent for “Selective Laser Sintering” and founded his first company. Competition in this field increased in 1989, which is also the year that witnessed the emergence of the company, “Stratsis”, the owner of the patent for FDM, short for the term “Fused Deposition Modeling”, which is the company that is still working in the field Same to this day.

So, the eighties of the last century marked the beginning of the launch of the 3D printing technology, and from that, this technology underwent great developments during the last decade of the same century and the first decade of the new millennium. This development focused at its beginning on industrial purposes, as patents that add new methods for the use of digitally designed models in the production and manufacture of prototypes.

3D Printing in the New Millennium:

From 1990 to 2000 Many 3D printers were developed with the development of CAD tools to keep pace with the development of printers, and also in the 1990s, the combination of 3D printing and medicine came to light, which opened the field for many applications.

In the year 2000, the first human kidney completely printed by 3D printing came to light, and after 13 years it was implanted in a patient to function completely normally.

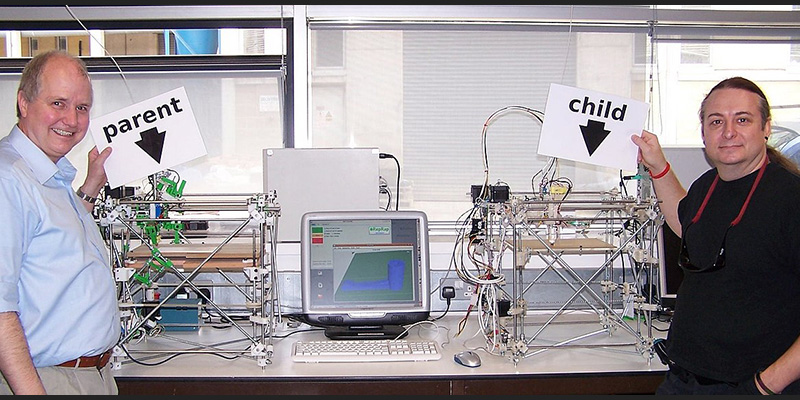

In 2004 The Open Source RepRap Project began, for office 3D printers to manufacture themselves, using FDM: Fused Deposition Modeling, which led to the technology being widely spread.

3D printers were characterized by their remarkable high prices until the company “3D Systems” launched in 2007 the first integrated 3D printer at a price less than $ 10,000, and in 2009 the world witnessed the unveiling of a printer BfB RapMan that has made 3D printing easier and more popular, and it established the printers that we see today on the market and are used in many different fields.

In 2008, Another achievement of 3D printing took place when the first artificial limb was manufactured.

The year 2009 was the year in which “Fused Deposition Modeling” was released into the public domain, opening the horizons for a big wave of innovations that would make printing easy. And in 2010, the technology invaded the market, whether it be in-office use or industrial use, as it made the industrial sector reconsider manufacturing. In addition to a reliable method, and during the same year, the first model of a car made by 3D printing was manufactured.

And in 2011 Cornell University began building a 3D printer to print food, which may seem unimportant, because there are a lot of people who will ask what is the need to build a printer to print food? The fact is, NASA is researching how astronauts can use it in space. And if you don’t know yet, Nasa’s research and technology is the root of advanced computer, smart phones and cameras tech we have today because in space everything is scarce and costs a ton of money so making things smaller and more efficient is one of their top priorities.

In 2013, 3D printers have attracted worldwide attention, and even in Japan, it has become a booming industry, and it has been the year when many services using 3D printers have appeared.

In 2014 NASA sent the first 3D printer into space to print the first printed part outside Earth. and in the year 2016, Another paradigm shift for 3D printing in healthcare was the research on Bone and Cartilage Printing with Bio Ink by Daniel Kelly.

Regardless of the progress we made, we have not yet reached the limits of what we can achieve in the field of 3D printing, because we are witnessing a new industrial revolution. In 2019 a group of surgeons at the Tokuda Hospital in Bulgaria replaced a tumor-containing rib with a 3D-printed prosthetic one to save a patient’s life.

In the same year, in a more recent development, Tel Aviv researchers have created the world’s first 3D printed heart with vascularization using a patient’s own cells and other organic materials. To this point, researchers have only been able to print cardiac tissues without blood vessels. This 3D printed heart made by Tel Aviv scientists, however, was created with full vascularization and marks a major breakthrough in the use of this technology.

3D Printing Nowadays:

The past five years we have witnessed an accelerated development and an expansion in the 3D printing market at the personal and commercial level, as the size of the 3D printing market reached 2.3 billion US dollars in 2013 and it is expected that the size of the 3D printing market will reach 8.6 billion US dollars this year in 2020 according to Forbes and may exceed the volume Market expectations of experts.

We are living in the third industrial revolution. Entrepreneurs have rushed to establish companies that rely entirely or partially on 3D printing technologies, some of which provide 3D printing services, and some manufacture 3D printers or manufacture raw materials, and some of them manufacture software for everything related to 3D printers.

Three-dimensional printing has invaded many fields, including, but not limited to, medicine, art, industry, etc. Among the most prominent applications of 3D printing in the manufacturing of experimental models, prosthetic limb industry, food industry, and other promising applications.

The main reason is the existence of difficulties and problems in the manufacturing and modeling market, and the existence of an urgent need to overcome these problems. 3D printing was the solution if not the best solution due to its low cost, ease, its different applications, and most importantly the abundance of raw materials.

3D printing can be used to manufacture various parts, regardless of their complexity. Before, it was difficult to do this compared to using traditional methods to manufacture them if not impossible. But now things have changed.